Drill Drone

Customers initial situation

The customer had an idea for an innovative application of multirotor aircraft, including a utility model. He wanted a flying demonstrator as a proof of concept.

Special challenges

The drilling module had to be completely designed from scratch with low weight and small size, as such a product was not available on the market.

Custom solution

A demonstrator was built and tested in flight to show that the concept was fundamentally feasible. Additionally, a theoretical study was conducted to identify the limits of the concept regarding ceiling material and the size of the aircraft.

An article on the project was published in the German magazine “Drones”.

Customer

Christoph Kunz, Inspirationsquelle, Germany

Year

2022

Project duration

12 weeks

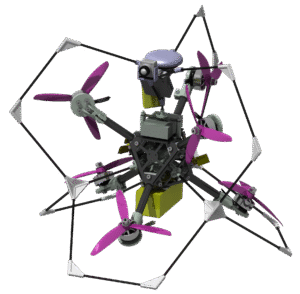

- Concept study on the feasibility of drilling in building ceilings using multirotor aircraft

- Design and construction of a flying prototype

- Autopilot adaptation for tilting propellers

- Software development for controlling the drill head (coordination of drill motor and feed motor)

Lynchpin

Customer’s initial situation

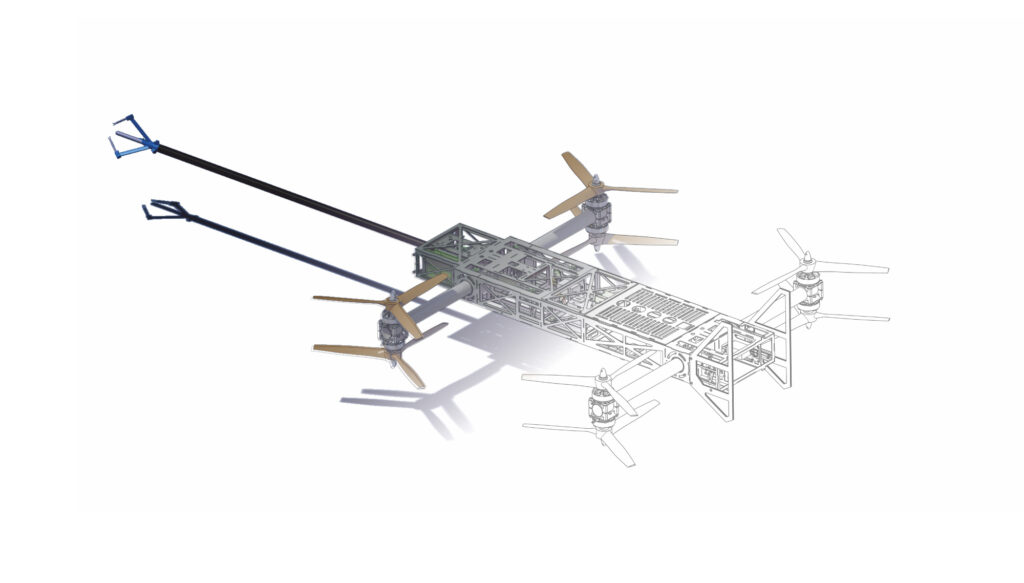

Oscar-nominated Hollywood actor Terrence Howard designed an innovative geometry for a multirotor aircraft. However, he had no prior experience with the design or construction of drones.

Special challenges

At the time, it wasn’t possible to fly a 6DOF drone with PX4 or ArduPilot without modifications to the code. In addition to deriving the mathematical equations, it was also essential to know and model the exact thrust curve of the propulsion system in order to achieve stable manual flight without GPS.

Custom solution

With the help of 3D printing and CFRP (Carbon Fiber Reinforced Plastic) milled parts, a flying prototype was built. The software was gradually adjusted until full 6DOF flight was achieved.

Customer

Terrence Howard, Tangential Flight Corporation, USA

Year

2021

Project duration

5 Months

- Development of a Control Concept for a 6 DOF Drone

- Measurement of a Rotor System for System Identification of the Propulsion Systems

- Fabrication of a Flying Prototype

- Flight Testing to emphasize the potential of the invention

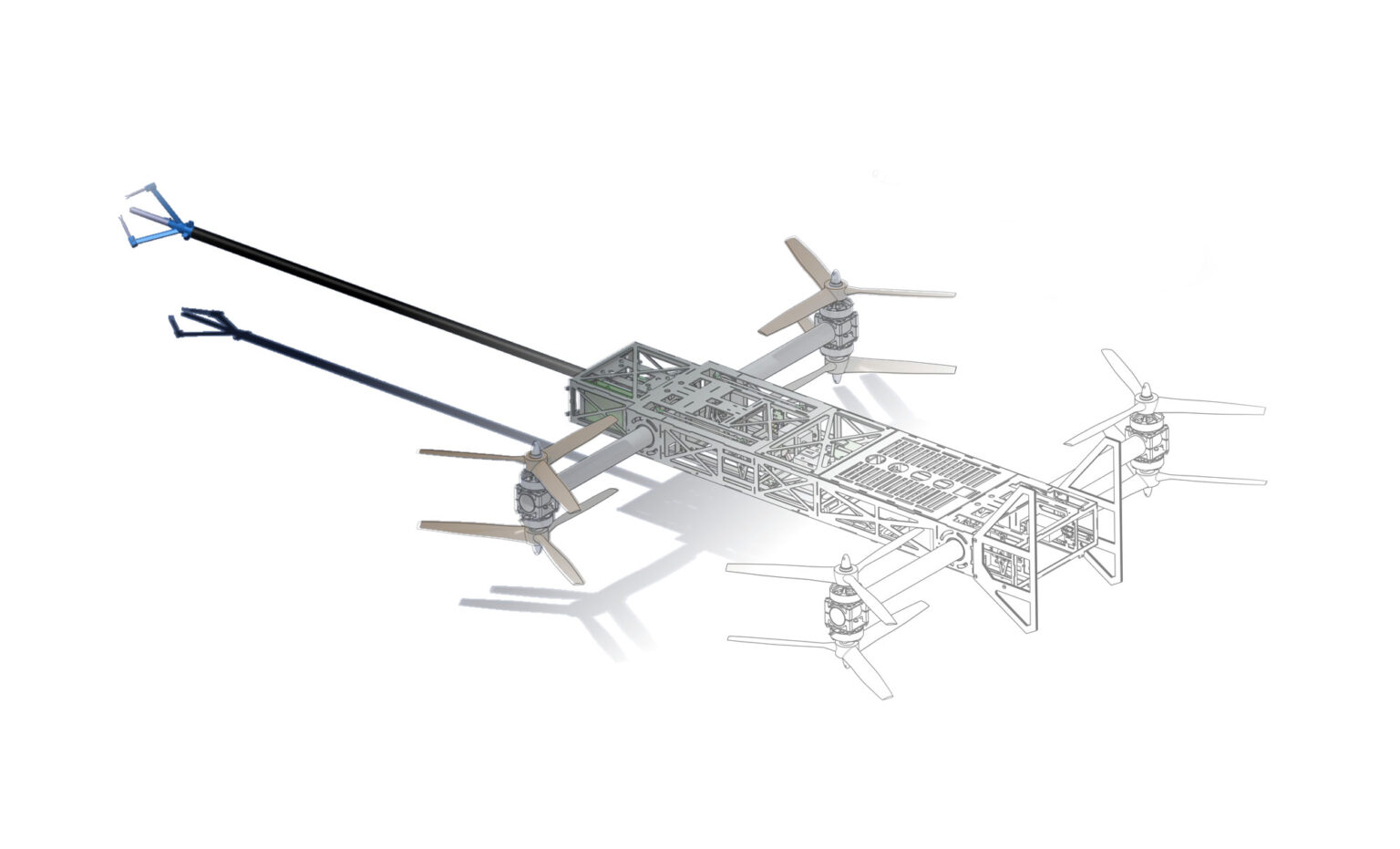

ANDroMeDA – ANWIND Drone for Measurement and Data Acquisition

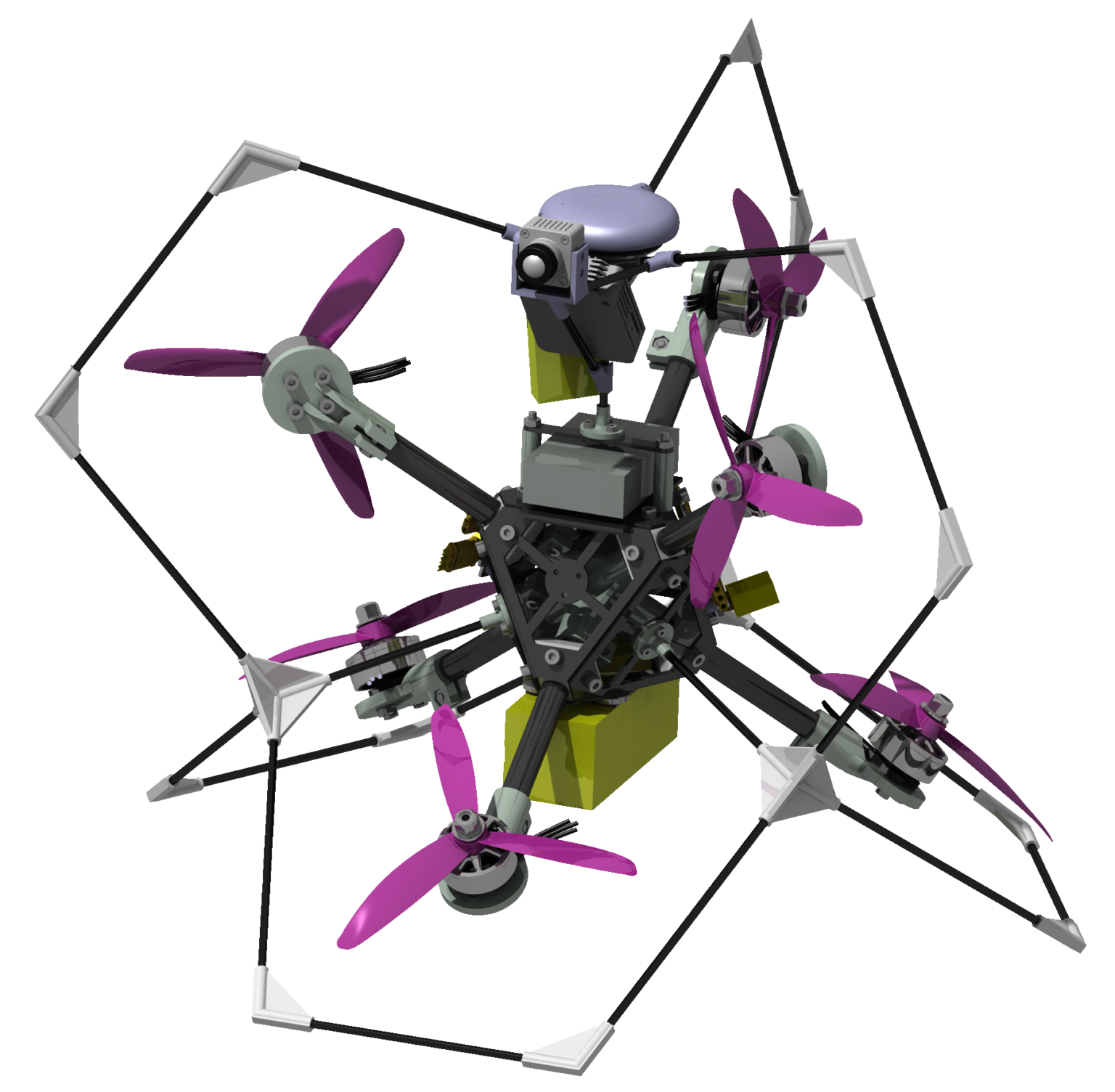

Four ANDroMeDA drones were built by 2020 during Dr. Christian Molter’s doctoral project at the Chair of Wind Energy at the University of Stuttgart, as part of the ANWIND project funded by the German Ministry for Economic Affairs and Energy.

Initial Situation

A drone had to be developed for wind measurements for research purposes. Multiple of such drones should be used to obtain a three dimensional information about the wind field, for example in complex terrain.

Special Challenges

The aircraft had to be able to compensate for sudden wind direction changes and wind gusts. Since the aircraft rotors will create a strong wake the measurement equipment could not be placed close to the rotors.

Custom Solution

Tilting propellers were incorporated into the design, enabling flight control through propeller adjustment rather than by moving the entire airframe. As a result, aircraft movements do not interfere with the measurements when compensating for wind gusts. Additionally, the measurement boom was frequency-tuned, and a notch filter was integrated into the flight controller to avoid oscillations of the measurement boom and to further enhance signal integrity.

A comparison between conventional measurement data from a sonic anemometer mounted on a meteorological mast and data collected by the drone demonstrated excellent agreement. A patent application for the novel design has been successfully filed.

Client

Dissertation

Year

2018-2020

Project Duration

2 Years

- Fully integrated measurement system with live preview on the ground

- Custom developed aircraft especially for wind measurement

- Highly customized approach with tilting propellers

- Takeoff/landing in nose-up position

Further references

https://elib.uni-stuttgart.de/items/e7e1b7e2-4d89-49aa-9d52-d068c71e9953

Measurement Equipment:

The measurement equipment using hot wire anemometry was devloped in cooperation with SVMtec GmbH: